Jul 29, 2011

Project Overview

The Bozeman Fish Technology Center is a 53,822 GSF Fish Research Center located in Bozeman,

Montana. The Center consists of 15 buildings including office space, storage, laboratories, fish production

and research buildings, as well as housing and a maintenance shop. Abraxas Energy Consulting

conducted an ASHRAE Level II audit.

The Solution

The first phase of the audit process consisted of a utility summary and analysis on the latest 12 months

of utility bills for the site. This analysis generated a baseline for the energy usage and utility costs, which

was used in calculating potential energy savings. Annual utility cost was $131,676 for electricity and

$87,409 for natural gas.

During the on-site inspection all the relevant information on the existing building conditions was

collected. This on-site assessment included reviewing building and equipment data, interviewing

site personnel, observing energy related equipment operation, and conducting some limited site

measurements. Based on inspections and calculations a list of 19 Low Cost Energy Conservation

Measures (ECMs) were developed, as well as a list of Administrative and Operational Measures that can

be implemented at very low cost.

Results

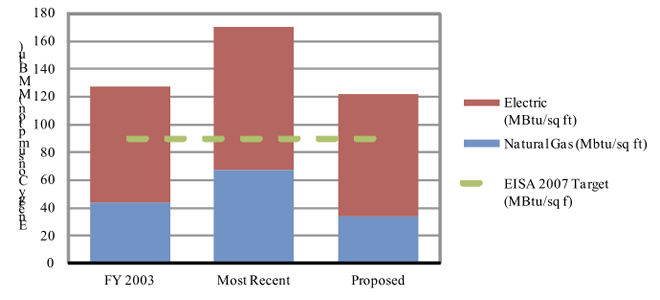

The ECM’s included programmable thermostat installation, variable frequency drives on pumps, occupancy controls, lighting replacement, window replacement, and heat recovery to preheat combustion air. Once the recommended measures are implemented, the energy usage and costs should be reduced by 28% and 19% respectively, which brings the organization closer to meeting EISA 2007 goals. The Most Recent or Baseline Energy Usage Index (EUI) for the building is 170 MBtu/ft2/year; if implemented, the recommended measures are expected to reduce energy consumption to approximately 122 MBtu/ft2/year.

Benefits

The ECM’s resulted in $32,266 savings per year with a simple payback of 3.7 years. Energy savings of 224,120 kWh/yr and 18,066 Therm/yr were identified. All values were evaluated using bin simulations and spreadsheet calculations based upon standard energy savings estimating methods and known and assumed operating conditions. Various incentives were identified through utility companies and various federal programs.